Flat Bottom Silos |

Flat Bottom Silos – Precision, Efficiency, and VersatilityFlat bottom silos are specifically engineered with a flat base, making them the perfect solution for permanent, high-volume, long term storage needs. The design incorporates advanced sweep augers, ensuring efficient material discharge and smooth operations even when handling large quantities of stored material. Rostfrei Grain Storage Silos are customised to perform in every Unique Challenging Condition, with primary focus to maintain grain quality.. Flat Bottom SilosOur range of this type of Silos in diameter from 9.14 Mtr with capacity 500 MT to 31.97 Mtr with capacity 15000 MTKey Advantages of BSSPL Flat-Bottom Silos⦁ Designed to PerfectionOur in-house design team, equipped with the latest design software and tools, creates silos to international standards. This ensures exceptionally durable silos with a design life of over 40 years. Part detailing is done using advanced 3D software for utmost precision. ⦁ Precisely ManufacturedWe utilize imported machinery from the US and Europe for turret punching and laser cutting. CNC-based operations guarantee the accuracy of every component, ensuring hassle-free installation and zero maintenance or repairs after installation. ⦁ Quality PreservationBSSPL Silos are designed not only to store grains effectively but also to maintain their quality throughout all seasons. We go the extra mile by offering customized steel grades, condition monitoring accessories like temperature monitoring and controlling, and a user-friendly operational interface. Crucial operations are automated to preserve grain quality, regardless of operator error. ⦁ High-Capacity Storage:A single unit of BSSPL Flat Bottom Silo can store 15,000 metric tons of grain, offering exceptional capacity for large-scale storage. ⦁ Enhanced Durability:BSSPL Steel Silos are constructed from high-grade steel with protective coatings and additional corrosion-resistant measures. Every silo undergoes rigorous design life tests, including Finite Element Analysis (FEA) and load analysis, to ensure it performs optimally at the installation site. ⦁ Customization:Each BSSPL Silo is fully customizable, from dimensions and material of construction (MOC) to accessories and design parameters, ensuring that all project’s unique requirements are met. Key benefits of the Storage of the Grain in the BSSPL SilosGrain storage silos play a crucial role in ensuring food security and maintaining the quality of harvested grains. By storing grains in a controlled environment, silos protect crops from weather, pests, and other contaminants, minimizing losses and enhancing food availability throughout the year. Efficient Space Utilization:Silos are designed to store large quantities of grain in a relatively small footprint, making them ideal for maximizing storage efficiency. Controlled Environment:With proper ventilation and temperature control, silos help preserve grain quality by reducing the risk of spoilage. Cost-Effective:Wall panels are profiled and curved using CNC corrugation machines, ensuring uniformity and strength. Automation:Fabricated parts undergo hot-dip galvanizing with a coating of over 500 GSM to enhance durability and corrosion resistance. Sustainability:Throughout the production process, multiple quality checks are conducted to ensure the highest standards: |

Hopper bottom Silos

|

Hopper Bottom SilosHopper Bottom Silos are designed for efficient storage of all types of grains, pulses & commodities with higher oil content like DOCs, Animal feed pellets Ranging from diameter 3.65 meters to 10.05 meters. Hopper Bottom Silos are precisely manufactured on CNC Based machines in accordance with American Standard ANSI / ASAE Standards or European Standard EN 1993-4-1 EFFICIENT STORAGE OF HIGH OIL CONTENT COMMODITIESBhagirathi Steels Hopper Bottom Silos are designed to ensure free flow of commodities with high Oil content/ moisture content like DOCs, Feed Pellets etc. through efficient design, Hopper angles ranging from 45 degrees to 66 degrees, and Coupling Bin-activators with hopper wherever Zincalume Roof further reduces moisture migration in the commodity ensuring free-flow. DURABILITYBhagirathi STEELS silos are designed adhering to International Standard on Precision CNC based machine, Utilizing Raw Materials from Topmost manufacturers & following Exhaustive Quality checks after every consecutive manufacturing process. VERSATILITYThe versatility of our HOPPPER BOTTOM SILOS makes them available for different industries such as breweries, animal feed, port facilities, Grain mills, ethanol plants, Solvent Plants, Raw Material for Plastic industry, Truck dispatch Silo and Live stock feed PEACE OF MINDMinimum Maintenance , Cost-effective & Prompt after-sales Service ensures that you focus only on improving milling efficiency and Business Gains. |

Chain Conveyor (up to 400 TPH) |

Material Handling EquipmentChain ConveyorThe fowler Westrup bucket elevator type is suited for transportation of cereals, seeds granular products and similar materials, also suitable for oleaginous seeds. The El elevators are delivered with the following features. Standard height is 4.0m. The elevator contains a number of leg sections plus a head and boot piece with pipe connections between these. One of the leg sections is fitted with access for belt mounting. The Westrup Bucket elevator is also available in a special type. We designed it for agricultural commodities calling for a self –cleaning transport system and /or fragile grain products, such as beans, peas, corn, peanuts, vegetable seeds, food grains or any free flowing crops. Bucket ElevatorA Bucket Elevator for Grain Loading can elevate from short to strong and from good to big lumps a range of mass products. Bucket Elevator for Grain Feeding may be a vertical or bent centrifugal storage elevator. Vertical elevators or Bucket Elevator for Flour Handling rely completely on the centrifugal force intervention to get the product into the disposal chute and must operate at comparatively elevated rates. Inclined elevators with buckets separated or placed near together may have the chute of release laid partially under the pulley of the neck. Since they are not completely dependent on the centrifugal force to bring the stuff into the chute, the velocity may be comparatively smaller. With little or no clearance between them, the buckets can also be triangular in cross section and set close to the belt. This is a constant elevator for the bowl. Its primary use is to perform slow velocity with hard components. Early bucket elevators used a flat chain connected every few inches with tiny steel buckets and for All kind of Powder Feeding Conveying. While some elevators are still produced with a string and steel buckets, a rubber strap with plastic buckets is used in most present bucket elevator building. Pulleys are used in the top and underside of several feet in diameter. A powered engine drives the bottom pulley. SALIENT FEATURES OF Bhagirathi STEELS MATERIAL HANDLING EQUIPMENTS –Versatility: For Variety Applications In Grain Industry To Convey Grains,pellets And Powdery Material- Bhagirathi Steels Manufactures Bucket Elevator, Chain Conveyor

|

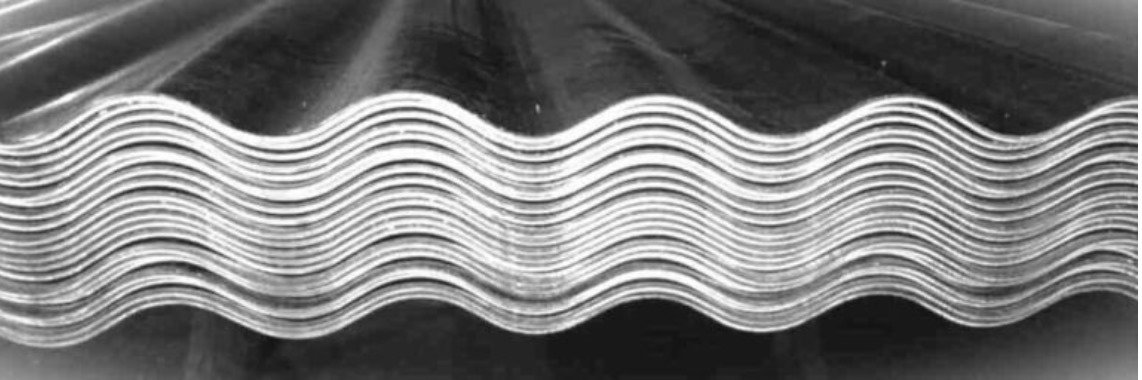

| <5>The Wave design of our wall sheets

with a gentle radius means more strength and better silo cleaning, improving materials unloading without any residue remaining so products are not contaminated. Wall sheets(Side walls) are processed on the dedicated CNC machine where profiling is being done so the sheets could withstand the load of the grain in the silos and pitch and depth of corrugations are considered to provide the better strength to the silos. |

|

We install 8.8-10.9 grade quality boltsminimum on all our silos with hot dip galvanisation coating with minimum average coating thickness of 40 to 50 micron, depending upon the galvanisation standard. Our silos with a cylindrical body and 31-degree slopped conical roofare designed to store the grains, seeds and palletized products. Process and Technology:The process of creating BSSPL flat bottom silos involves a series of precise steps, ensuring the highest quality and integrity of the final product: tank CNC Drilling for Nut & Bolt Holes:The preparation of nut and bolt holes is done using advanced CNC machinery to ensure precision. CNC Bending Process:Components are bent using high-precision CNC machines for accuracy and consistency. Profiling and Curving of Wall Panels:Wall panels are profiled and curved using CNC corrugation machines, ensuring uniformity and strength. Hot-Dip Galvanizing:Fabricated parts undergo hot-dip galvanizing with a coating of over 500 GSM to enhance durability and corrosion resistance. Quality Checks:Throughout the production process, multiple quality checks are conducted to ensure the highest standards: In-Process Quality Check:Continuous monitoring during production to ensure adherence to specifications. Internal Quality Check of Materials:Rigorous inspection of incoming materials to ensure they meet our high-quality standards. Pre-Dispatch Inspection:A final comprehensive inspection before shipment to verify the quality and readiness of the product. Proper Packaging:Materials are carefully packed for transport, using pallets, crates, wooden boxes, and stands to ensure safe and secure delivery. Applications:

|